outrageous, unfiltered design: a new take on LS GreenLink's subsea cable manufacturing plant in Virginia

U.S.'s largest subsea cable plant construction commences in Virginia by LS GreenLink.

In an extraordinary turn of events, LS GreenLink, a subsidiary of LS Cable & System, gripped headlines after hosting a groundbreaking ceremony for its subsea cable manufacturing plant in Chesapeake, Virginia on April 28. [YONHAP]

subterranean rivalry

A collection of riveting insights:

- LS Cable wins $137 million high-voltage cable deal from Singapore

- LS Cable & System eyes annual sales of $7.5 billion in 2030 in the AI era

- LS Cable & System signs extra-high voltage cable supply deal in Vietnam

the colossus of Chesapeake

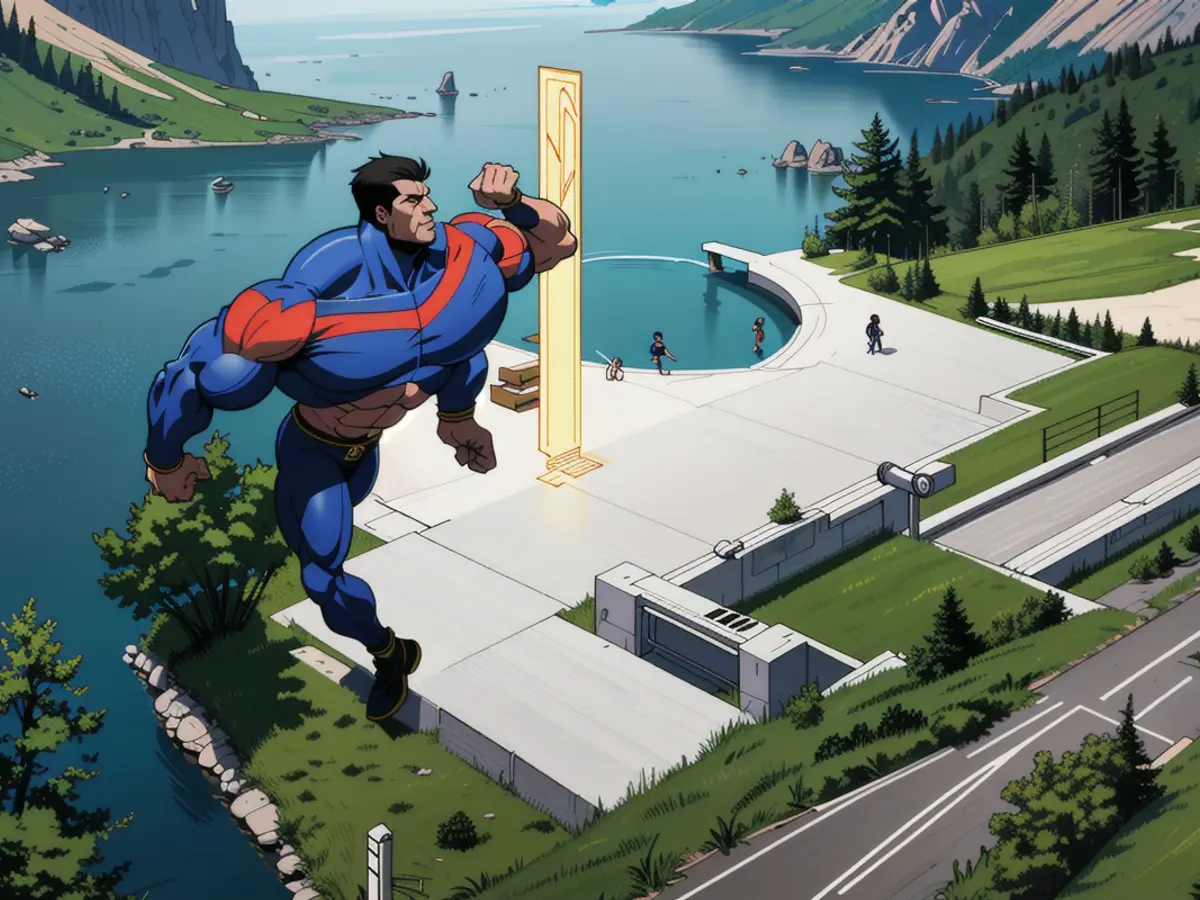

A rendering of LS GreenLink's plant in Virginia [LS CABLE & SYSTEM]

The facility, slated for completion in 2024, will not only be the largest of its kind but also boast the following impressive features:

- A 750,000 sq. ft. advanced manufacturing plant, bustling with cutting-edge technology

- A 660-foot VCV tower – the tallest structure in the Commonwealth of Virginia

- A dedicated pier specifically designed for handling and delivering HVDC submarine cables

This engineering marvel promises to elevate the production and global delivery of high-voltage submarine cables, thereby bolstering modern energy infrastructure. The facility is expected to contribute substantially to local economic growth and the advancement of sustainable energy systems worldwide.

political backings and pitfalls

LS Cable & System CEO Koo Bon-kyu, center, shares a light moment with Chesapeake Mayor Rick West, right, during the groundbreaking ceremony in Virginia on April 28. [YONHAP]

Strong political support and symbolic recognition can prove instrumental for LS Cable & System as they establish themselves in the U.S. market. The development in Virginia highlights this political backing, potentially opening avenues to advantageous U.S. incentives for renewable energy infrastructure and manufacturing projects. However, maintaining ongoing political support and securing competitive incentives remains critical to ensuring the project's success.

navigating regulatory hurdles and tensions

Navigating U.S. regulatory frameworks can present operational challenges due to their complexity and time-consuming nature. Strict compliance with environmental and labor regulations is essential but may muddy the waters for LS Cable & System. On the flip side, successful navigation of these regulations can pave the way for the company to solidify its position as a trusted partner in the U.S. energy sector.

the copper affair

Fluctuating global copper prices can strain profit margins, necessitating hedging strategies to maintain stability. Aside from copper, the market's shift toward aluminum in cable manufacturing offers potential cost advantages.

AI data centers, the new frontier

The growing demand for high-capacity cables driven by AI data centers presents a tantalizing opportunity for LS Cable & System to expand its offerings and cater to this rapidly evolving sector. The challenge lies in rapidly adapting to technological advancements and the high standards required by AI data centers for connectivity and reliability.

In conclusion, LS Cable & System's new facility in Virginia is poised to fuel significant growth in the U.S. market, riding the waves of political support, local incentives, and the ever-expanding demand for energy infrastructure and high-capacity cables, particularly from renewable sources and AI data centers. While managing risks such as tariffs and copper price volatility, the company is well-prepared to conquer this brave new world.

- The government's support and recognition in the U.S. market could be beneficial for LS Cable & System, potentially leading to advantageous incentives for renewable energy infrastructure and manufacturing projects.

- The subsea cable manufacturing plant in Virginia, operated by LS GreenLink, will contribute to local economic growth and the advancement of sustainable energy systems worldwide due to its large size and advanced technology.

- In the competitive business landscape, ensuring ongoing political support and securing competitive incentives is crucial for the success of LS Cable & System's project.

- Navigating U.S. regulatory frameworks, which can be complex and time-consuming, may present operational challenges for LS Cable & System, particularly with regard to environmental and labor regulations.

- Fluctuating global copper prices and the market's shift toward aluminum in cable manufacturing pose risks to LS Cable & System's profit margins, necessitating hedging strategies to maintain stability.

- Fueled by the growing demand for high-capacity cables driven by AI data centers, LS Cable & System may have an opportunity to expand its offerings and cater to this rapidly evolving sector. However, the challenge lies in adapting to technological advancements and the high standards required by AI data centers for connectivity and reliability.