Precision readjustments are a common aspect of clock repair work

================================================================

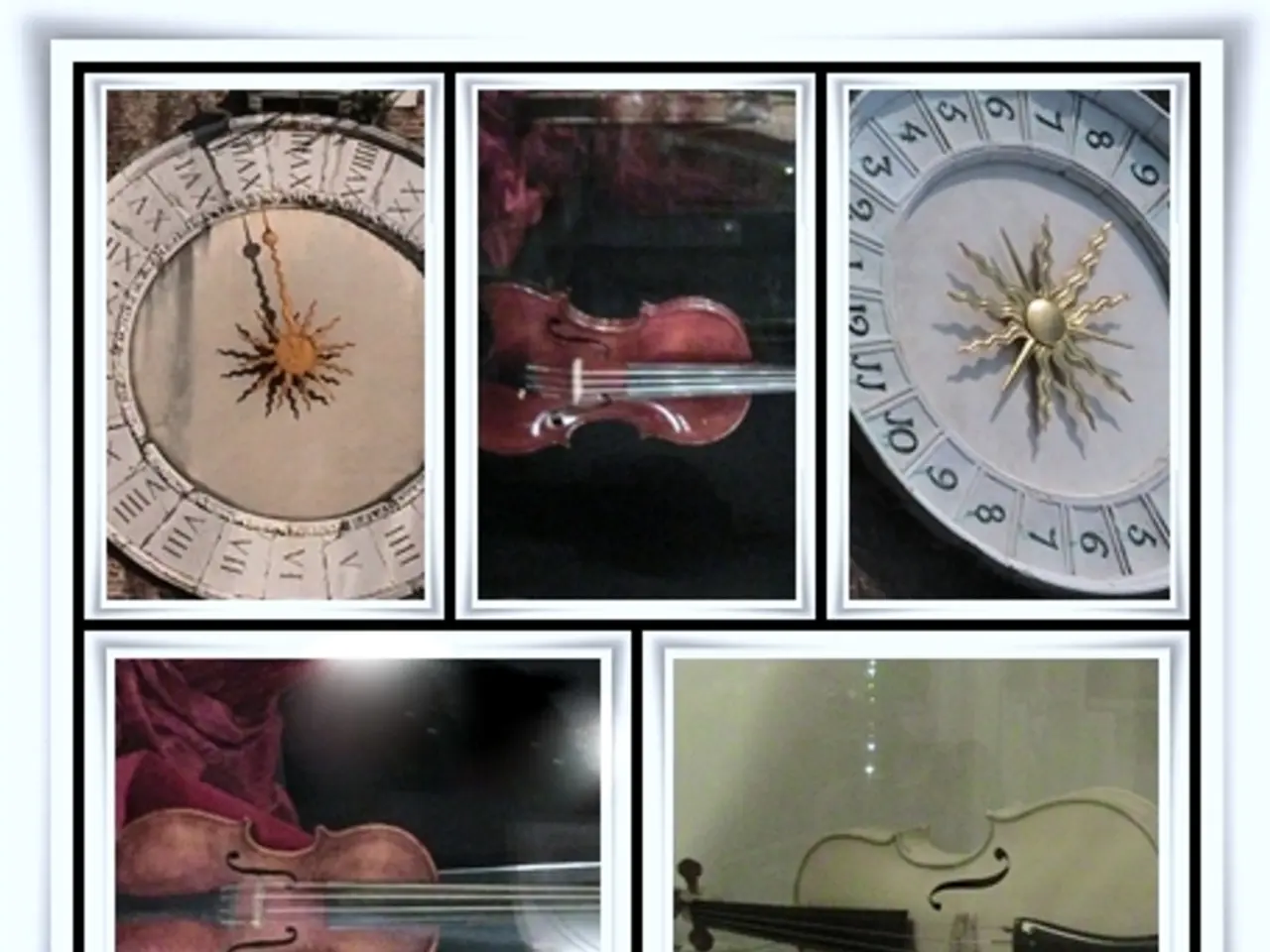

A recently serviced Mauthe box clock, which was likely sold under the Forestville or Solar name in department stores across Canada in the 1940s, has captured the attention of horology enthusiasts. Despite last seeing a servicing in 1979, the clock remains in good condition.

The clock's German movement is intricate and requires careful attention to detail during assembly and disassembly. For instance, putting the movement back together requires mindfulness of small pivots to avoid bending or breaking them.

Two critical adjustments before assembling the plates are the placement of both the stop or warning wheel and the star wheel. The star wheel, which controls the striking sequence, should be positioned so that its teeth properly engage the hammer arbors' lift levers or cams to ensure a correct bim-bam pattern.

The star wheel is aligned such that one star tooth lifts one hammer arbor to strike the first bell (bam), and the next star tooth lifts the other hammer arbor to strike the second bell (bim), producing the alternating bim-bam strike rhythm. This requires the star wheel to be indexed carefully relative to the hammer arbors so the gaps between its teeth correspond precisely with the hammer lifts.

For accurate adjustment:

- Verify that when the star wheel tooth rotates, it only lifts one hammer arbor at a time.

- The timing between strikes must allow the hammers to fall and prepare for the next strike.

- The star wheel must be correctly aligned with the hour and quarter-hour striking sequence cams to maintain proper bim-bam cadence.

If the star wheel is misaligned, the hammers may strike improperly (e.g., simultaneously or out of sequence). Correct positioning often requires fine adjustment by trial, ensuring smooth alternation. Unfortunately, specific information about the correct positioning of the star wheel relative to the hammer arbors in a Mauthe box clock with a bim-bam strike was not found in the searched sources.

The clock, a Mauthe box clock, does not have the Mauthe trademark or name. However, it does have a two-rod gong, which was made by Divina, a subsidiary of Mauthe. The stop or warning wheel requires about half a rotation to arrest the train during the warning phase.

Fine-tune adjustments are part of the experience in clock repair, and this Mauthe box clock is no exception. The search results did not provide explicit details on this specific setup, but consulting a Mauthe repair manual or a clockmaker experienced with bim-bam mechanisms is recommended for precise instructions and diagrams.

- In the pursuit of restoration, a skilled clock repair professional might find it beneficial to consider pairing the vintage Mauthe box clock with a modern smart-home-device, allowing the vintage clock's bim-bam strike to synchronize with other gadgets and technology in a smart home.

- As one peruses the market for clock movements, the intricate mechanism of the Mauthe box clock might remind someone of the precision engineering found in contemporary clock movements, thereby bridging the gap between vintage clocks and the advancements of technology.

- The next time you're browsing through a collection of gadgets and technology, spare a thought for the beauty and artistry that goes into crafting a classic vintage clock like the Mauthe box clock and appreciate the enduring allure of these mechanical marvels.