BMW trials autonomous driving in unconfined settings at its Regensburg manufacturing facility

Taking a Leap in Digital Manufacturing: BMW's Autonomous Vehicle Revolution

Of late, BMW's Plant Regensburg has been making waves, as it's the latest hub to adopt driverless vehicles in its operations - a stride forward from the trails set in Dingolfing and Leipzig. This technological leap is a part of BMW's broader vision to create an intelligent, networked, and digital production facility, known as the BMW iFactory.

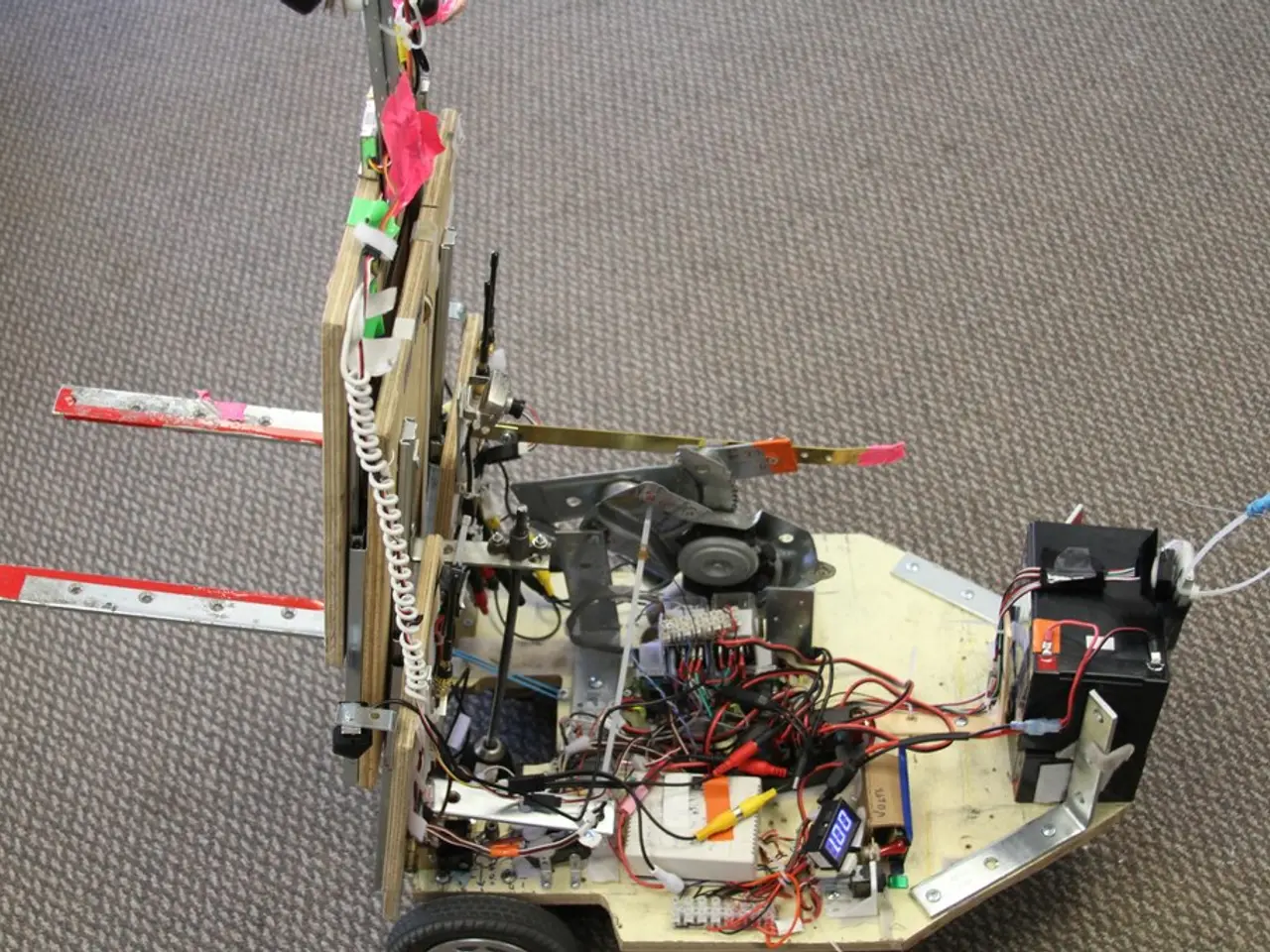

Once off the final assembly line, the sleek, completed cars navigate the plant autonomously to reach the yard for loading. Instead of depending on vehicle-mounted sensors, an external radar and LiDAR sensor infrastructure keeps watch. These sensors, along with motion planning software, control the vehicles in real-time via wireless networks and a cloud-based architecture.

Plant manager Armin Ebner asserts, "Our adoption of automated driving kicks off another phase in the efficiency of our logistics. It's a significant step towards the BMW iFactory, embodying our vision of a smart, connected, and digital manufacturing facility."

Implementing this new technology in the Regensburg plant has been no small feat. Klaus Grabinger, the project leader, explains the hurdles, "In Regensburg, we've taken autonomous driving outside for the first time, meaning we also had to consider weather conditions." This precaution guarantees smooth navigation through slippery or rainy conditions, ensuring the light-based sensor technology remains effective even during low-lying evening sun.

Prioritizing employee safety and process reliability, double-flashing warning lights signal when a vehicle is autonomous. The system can halt a vehicle instantly should an obstacle appear. The system's safety has received approval from TÜV after extensive testing.

As for the future, BMW plans to widen the application of this Autonomous Förder Walk (AFW) technology across its global production network. Insights gleaned from the Regensburg plant are already being implemented at the new plant site in Debrecen, Hungary, where vehicles will soon navigate autonomously over open fields.

While the automotive industry faces challenges like ensuring system reliability, addressing potential software glitches, and maintaining cybersecurity, the embrace of autonomous vehicles is an undeniable step towards a future where manufacturing and transportation processes intertwine to create a world of seamless efficiency.

- In the future, BMW plans to extend the application of the Autonomous Förder Walk (AFW) technology, which is currently being used at Plant Regensburg, across its global production network, including the new plant site in Debrecen, Hungary.

- At Plant Regensburg, BMW has implemented other technology such as radar and LiDAR sensor infrastructure, motion planning software, and wireless networks to control the autonomous vehicles in real-time via a cloud-based architecture.