Benefits of High-Density Interconnect Printed Circuit Boards and Their Usage

In the ever-evolving world of technology, High-Density Interconnect (HDI) Printed Circuit Boards (PCBs) are making a significant impact. These advanced PCBs, characterized by their compact size, high component density, and improved electrical performance, are transforming various industries.

HDI PCBs are finding their way into the medical industry, where they are used for small devices like implants, lab equipment, and imaging equipment. In the automotive sector, HDI PCBs are being employed to save space, particularly in futuristic cars. The automotive industry is not the only one benefiting from HDI technology; it is also incorporated in military communications devices and strategic equipment like missile and defense systems.

One of the key advantages of HDI PCBs is their ability to miniaturize. Compared to traditional PCBs, HDI PCBs can reduce board size by up to 60%. For instance, a standard 6-layer PCB might be replaced by a 4-layer HDI PCB, achieving substantial miniaturization. This miniaturization is also evident in the consumer market, with HDI PCBs being a major stakeholder, as seen in the launch of wearable technology like the Apple Watch and Virtual Reality headsets.

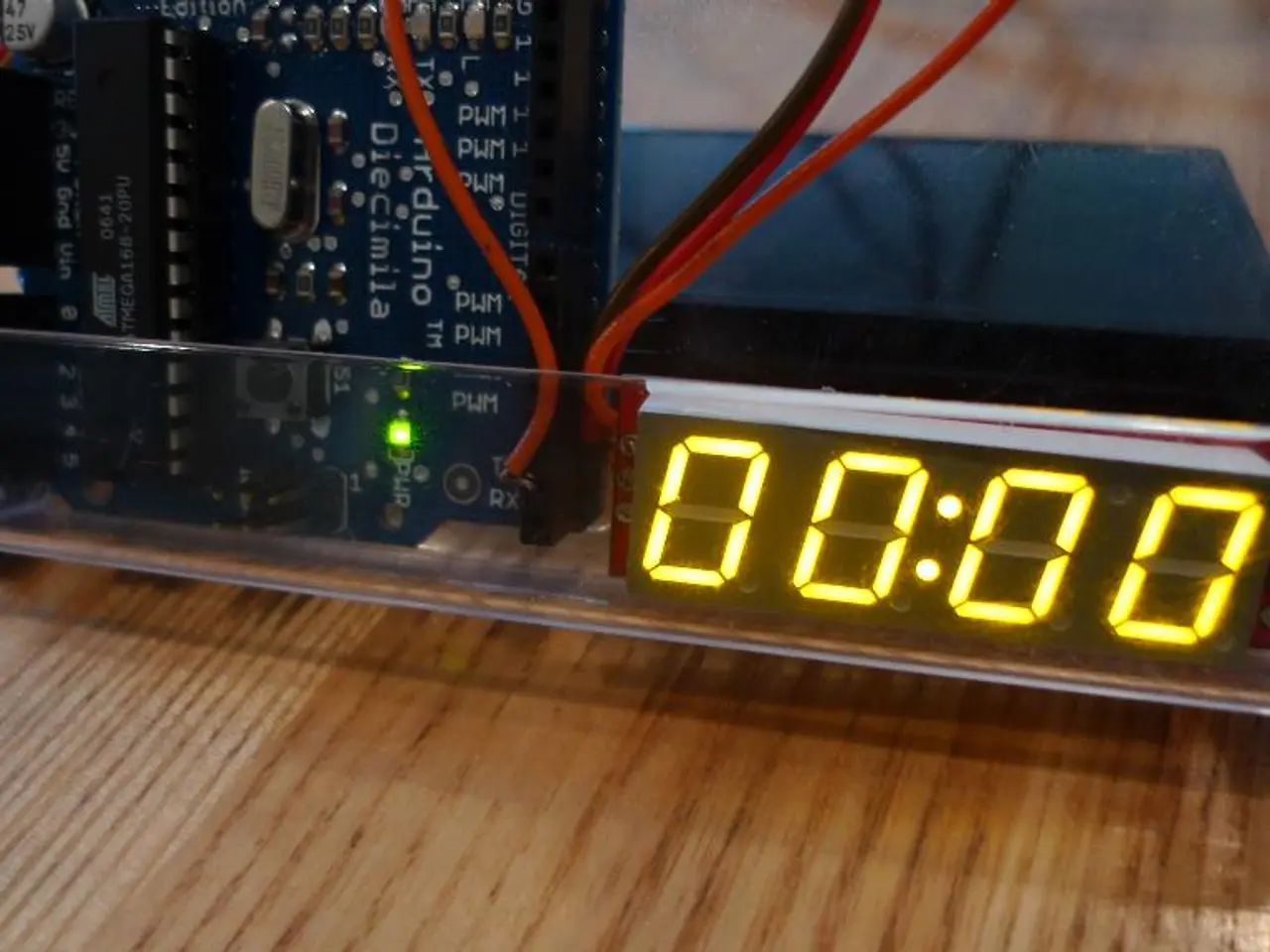

The high component density of HDI PCBs is made possible by advanced manufacturing techniques such as laser drilling and microvias, enabling much finer circuit features and smaller vias. This allows for more components and interconnections within a smaller area than standard PCBs, which have simpler designs with fewer interconnections.

The improved electrical performance of HDI PCBs is critical for high-speed applications and environments requiring reliable data transfer. Their smaller vias and dense routing improve mechanical stability and electrical reliability, especially under harsh conditions. This makes HDI PCBs ideal for high-functionality applications such as consumer electronics, telecommunications, and wearables.

However, the manufacturing of HDI PCBs involves more complex and expensive processes, resulting in higher initial fabrication costs than standard PCBs. Nevertheless, the miniaturization and integration can potentially offset these higher upfront costs by lowering material use, assembly complexity, and improving reliability.

For those interested in designing HDI PCBs, it is recommended to consult with the DESIGN SERVICE team for more information. It is clear that HDI PCBs have revolutionized the electronics industry and are used in every electronic gadget. The demand for PCBs looks promising as they are extensively used in various industries, making them an essential component in the technological advancements of today and tomorrow.

Technology, specifically High-Density Interconnect (HDI) technology, plays a crucial role in the manufacturing of HDI Printed Circuit Boards (PCBs), which are revolutionizing the electronics industry. These advanced PCBs, controlled impedance being one of their key features, are utilized in a range of applications, from miniaturized medical devices and automotive systems to high-speed consumer electronics and telecommunications equipment.